Change Language :

Across the project history - customised solutions

Frozen food vending machine

Seco's frozen food vending machine, the seco°mat, has a digital operating unit. It enables operators to offer various payment systems such as EC, credit card, RFID or ApplePay. The display can also be used for digital advertising. The customer has access to a shopping basket function and digital information fields for specifying allergens and ingredients. By integrating the Apiro® modular gearbox system, several challenges could be solved simultaneously: - Maintenance costs were minimised - Longevity was maximised - Costs were significantly reduced compared to comparable kinematics. - Thanks to the powerful worm gearbox, the opening of the cooling area could be integrated into the process, thus eliminating the need for an additional mechanism.

The challenge in this project was to find a solution for an existing system. Retrofit projects often leave little scope for standardised solutions. The Apiro® system was therefore customised into the vending machine housing.

Resistant to extreme temperatures

FDA-compliant thanks to the absence of lubricants

Low maintenance for autonomous use at the POS

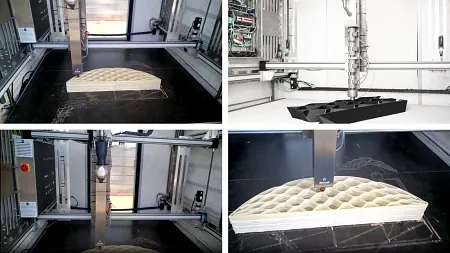

3D printer for house facades

With the KamerMaker project, the Amsterdam-based company DUS Architects has set itself the goal of creating entire houses from plastic waste. To this end, they launched a project with a number of industrial partners such as Henkel and igus® in which they regranulate plastic waste and have it printed into components for houses in an oversized container. The components can have a total volume of 2x2x3 metres and consist entirely of recycled plastic waste. The idea is then to send these mobile 3D printers to material yards around the world. A spatial gantry robot with stepper motor technology was used. The technical challenge lay on the one hand in the conditions such as the degree of the sea container, corrosion resistance and low weight of the structure, and on the other hand in the process of being able to reuse the plastic waste in a process-safe manner.

For this project, the room linear robot for the 3D printer in the overseas container had to be customised and programmed on site with a non-igus®-internal control system.

Oversized installation space

Operability despite uneven surfaces

Easy to transport

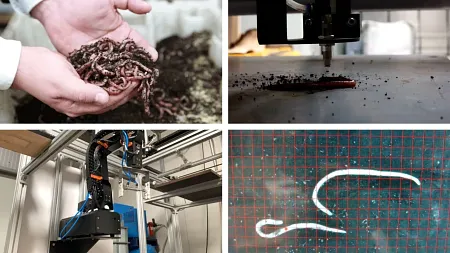

Automated earthworm breeding

In order to be able to breed earthworms economically in Germany, SUPERWURM relies on automation. The robustness of the components used and their costs play a decisive role here. This has led to the early use of igus® components in various applications. Specifications such as dirt resistance, corrosion resistance and robustness have played a major role here.

In this project, the challenge was to master the adverse conditions: dirt, humidity, FDA conformity, protection against corrosion of the components, etc.

As part of the project, the dimensions and the portal were planned and the service life for the warranty was calculated. In addition, the energy chain was planned and the integration on site was monitored.

Dirt-resistant

Lightweight

Resistant to high humidity

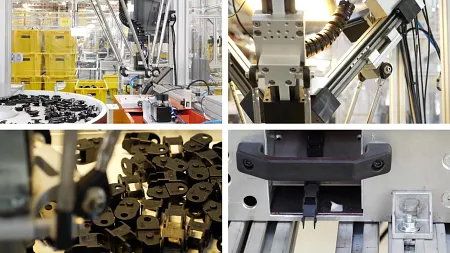

In-house assembly of energy chain links

In the application, plastic components are sucked in by the delta robot and placed in a holder. In the next step, the individual components are joined together. The challenge in this application was the precise processing of the camera data. The robot has a pick cycle time of 1-2 seconds. The components are jogged at random.

This project represents the highest level: Project planning of the machine including camera technology and control system, machine enclosure, CE labelling, documentation, operating instructions, etc. A plug and play solution for a quick start to an automation project.

High repeatability

ROI after approx. 2 months

Low maintenance for high output

We make a difficult automation solution very simple: customised solutions do not have to be expensive. With over 10 years of experience in the project business and more than 1,000 projects a year, we can draw on a wide range of modules and easily derive customised solutions from them. Avoid an oversized application "over engineering". We always develop the right technical solution at the best price.

Consulting

I look forward to answering your questions

Hennlich, d.o.o.+386 4 532 06 15Write e-mail

Shipping and consultation

In person:

Monday to Friday from 7 am - 8 pm.

Saturdays from 8 am- 12 pm.

Online:

24h

WhatsApp-Service:

Montag – Freitag: 8 – 16 Uhr