Change Language :

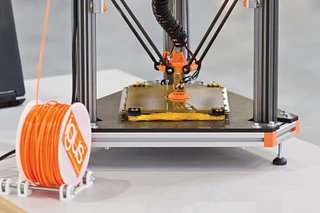

Lubrication and maintenance-free products for 3D printers

Components or ready-to-install system solutions for the design of 3D printers – suitable for every installation space

Lubrication-free and maintenance-free technologies and components from igus already play a key role in most construction kits and construction plans for 3D printers. Tribologically optimised plastics ensure improved 3D printing technology and reduce costs. With the motion plastics modular system, we offer maximum design freedom for self-built 3D printers: drylin linear plain bearings are virtually noiseless, as there are no metallic balls, and dryspin lead screw nuts ensure efficient and precise adjustment of the printing bed. In addition, our e-chains prolong machine running times, making corkscrew and general cable failures a thing of the past. Smallest installation spaces, tightest bend radii, short assembly times - Benefit from our wide range of products and order with no minimum order quantity.

Our engineers have developed a high-temperature printer especially for processing high-temperature filaments. You can simply download the design data and use it to build your own high-temperature printer:

Simply order 3D-printed components online

Do you need customised, wear-resistant components for the construction of your 3D printer or are you looking for solutions for the rapid production of abrasion-resistant prototypes or small batches?

Then use the igus 3D printing service: Simply upload your CAD, select the material and compare prices immediately. The finished components are ready to ship in 1 to 3 days. We also offer 3D printing materials for food contact, ESD protection, fire protection and other special properties.

Top products for use in 3D printers

Success stories

More information

Consulting

I look forward to answering your questions

Hennlich, d.o.o.+386 4 532 06 15Write e-mail

Shipping and consultation

In person:

Monday to Friday from 7 am - 8 pm.

Saturdays from 8 am- 12 pm.

Online:

24h

WhatsApp-Service:

Montag – Freitag: 8 – 16 Uhr