Change Language :

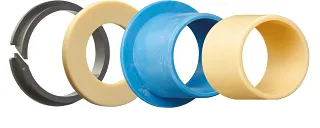

Maintenance-free iglidur® plain bearings made of plastic

Plain bearings are used to prevent direct contact, e.g. between shaft and housing, so that they do not wear out. Most bearings have to be lubricated regularly to function properly. iglidur plain bearings do not require additional lubricants, which makes them maintenance-free and a cost-effective alternative to metal plain bearings. They are available in various types and more than 10,000 sizes in our plain bearing online shop. With the iglidur materials specifically developed by igus it is possible to realise a wide range of applications for our plain bearings in various industries. They can be subjected to high temperatures, chemicals or high loads and are suitable for contact with food.

The advantages of our plain bearings at a glance

Try out the iglidur plain bearing online shop now

The iglidur plain bearing shop includes our complete catalogue range. It also allows users to calculate prices and delivery times for customised bushings in a matter of seconds.

For shaft diameters Ø3 - Ø195 mm

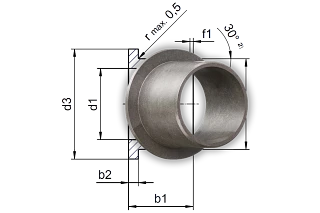

Flanged bearings

For shaft diameters Ø3 - Ø195mm

To the shop

Sleeve bearings

For shaft diameters Ø1.5 - Ø150mm

To the shop

Thrust washers

For axial bearing support

Ø8 - Ø114mm

Guide rings

For linear guides

Ø4 - Ø80mm

Clip bearings

For sheet metal feedthroughs

Ø8 - Ø25mm

Two hole flange bearings

For screwing

Ø10 - Ø35mm

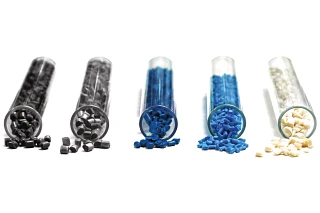

Our plain bearing materials

You can find an overview of our technical information and data sheets on our iglidur materials here and download them.

Learn more about the iglidur materials

PTFE-free and PFAS-tested plain bearing bushings

Due to the current discussion regarding a ban on PTFE and PFAS, we have compiled all important details about our plain bearings here. You will also find a list of all iglidur materials that do not contain PTFE or have been tested for PFAS that are considered critical or harmful to health.

Customised products and drawing parts

In addition to our extensive standard range, we also offer custom-made products according to your specifications . There are various manufacturing processes to choose from, meaning that we can always select the best offer for you.

Plain bearing wiki

- What are the sliding speeds of igus plain bearing materials?

- What coefficient of friction do igus bearings have?

- And what is the stick-slip effect?

These and many other questions are answered here. Find out everything you need to know about our plain bearings and materials.

igus new plain bearing products

Discover our new products in the field of bearing technology. Customer enquiries constantly present us with challenges that often lead to the development of new products. Our goal is to always offer our customers the most cost-effective solution and to enable technical progress.

Frequently asked questions about our products

Don't miss any more igus news

With our motion plastics news you won't miss any news about igus and its products. Our newsletter will keep you up to date: new products, exciting applications, current laboratory reports and much more.

Consulting

I look forward to answering your questions

Hennlich, d.o.o.+386 4 532 06 15Write e-mail

Shipping and consultation

In person:

Monday to Friday from 7 am - 8 pm.

Saturdays from 8 am- 12 pm.

Online:

24h

WhatsApp-Service:

Montag – Freitag: 8 – 16 Uhr