Change Language :

Tech up and cost down – with igus high-performance plastics

We set high standards for ourselves and our products: Improve what moves! Bearing technology, energy supply systems, Low Cost Automation, 3D printing, and smart plastics all have one thing in common: Their purpose is to improve technology and reduce costs. Ideally, we can achieve both: Tech up, cost down. To this end, we offer high-performance motion plastics that give you the following advantages, among others:

- Long service life

- No additional lubrication necessary

- Up to 70% less weight than metal products

- Resistant to dirt, chemicals, corrosion, heat and cold

THE advantage of our motion plastics: long service life - tested and guaranteed!

You can rely on our products made from high-performance plastics, for which we offer a 4-year guarantee. So that you know that this is really the case and exactly how long our motion plastics will last, you can easily calculate the service life in advance. Where do we get the data? From our test laboratory, which we have been operating since 1985 and which is unique in the industry with an area of 5,500m² and over 15,000 annual tests. And from our customers, whose requirements and feedback give us valuable information for developing our products. In addition, a growing number of our parts are available as smart plastics - they allow you to monitor their material condition and report a possible replacement in good time. All this leads to the long service life of our motion plastics, which is one of many advantages: tech up, cost down.

Find out more about our products on this page now

I have to understand 100% where the shoe pinches"

"I love solving problems. I am really pleased if one of our customers can be made happy as a result. Of course, this is only successful if I work very closely with the customer. I need to completely understand where the difficulty lies in order to find an individual solution. It is not uncommon for such individual solutions to result in new products that we include in our catalogue product range. Our customers therefore rely on our team as a driving force in the area of research and development."

Stefan Niermann, Vice President and Head of drylin Linear Technology & Low Cost Automation

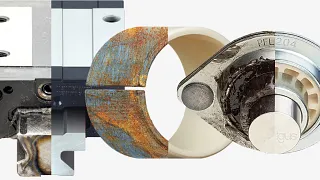

Bearing and linear technology: lubrication-free and durable

Our materials and bearing and linear technology designs are diverse: From plain, spherical, and ball bearings to slewing rings to gears to linear guides and linear axes, all of which can, for instance, be food grade, high load, or resistant to high temperature, chemicals, and UV. The core of our developments is friction optimisation. All material mixtures are optimised with filler and solid lubricants for low coefficient of friction, no external lubrication necessary. No lubrication intervals or maintenance interruptions. Our technology runs trouble-free for as long as conditions allow. And since our materials are tailored to many conditions, that can be a very long time compared to other materials.

Bearing technology from igus is

- lubrication-free

- corrosion-free

- lightweight

- easy to configure and order

Bearing technology from igus can

- save up to 89.5% in costs

- be a technical improvement

- be calculated in terms of service life

- be individually planned

Energy supply: reliable chain-cable combination

The best bearing technology cannot show its added value if the machine cannot run because it cannot get any energy. Data, power, and media cables are neuralgic points of a machine where the cause of a failure can often be found. Our energy chains, movement-optimised chainflex cables, and ready-to-connect readycables have been developed to prevent failures and allow long service life. They are available as individual components or complete ready-to-install energy supply systems.

Energy supplies systems from igus are

- simply assembled

- installed in a space-saving manner

- quiet whilst operating

- quickly retrofitted with individual cables

- resistant to wind, weather, dirt and chemicals

Energy supply systems from igus can

- save up to 64.7% costs

- save up to 88% installation time

- save up to 48% weight

- guide energy, data, air and media alongside each other

- be calculated in terms of service life and come with up to a 4-year guarantee

User reports on our products

motion plastics product samples

Would you like to experience our products up close, get your hands on them and "grasp" them in the truest sense of the word? That's exactly why we offer you various samples, such as the huge motion plastics sample crate, a customised sample box and many other product samples.